A Clear View of Cloudy Sprays

By Charles Q. Choi

Lasers and x-rays combined can capture quick-changing droplets as they break apart and evaporate.

Lasers and x-rays combined can capture quick-changing droplets as they break apart and evaporate.

Most cars still have internal combustion engines, and these engines work by spraying puffs of fuel into cylinders hundreds of times every minute—fuel that, when ignited, generates the explosions that move pistons and allow people to drive all across the planet. A critical part of the process is that the injected fuel must be vaporized fully prior to ignition; the presence of any liquid droplets leads to inefficient combustion and polluting soot. Scientists therefore would like to observe the fine details of how droplets break apart and evaporate. But more than a century after the invention of the automobile, peering deeply into that process remains challenging.

“You could think of trying to image a plane behind a cloud in the sky. In most cases, the plane is not even visible,” says Edouard Berrocal, a physicist at Lund University in Sweden.

E. Berrocal et al.

Now Berrocal and his colleagues have married two competing imaging techniques into one method that illuminates these sprays; it uses a combination of x-rays and near-infrared laser light to provide unprecedented views of droplet cloud structures. Their research, detailed in the February 20 issue of the journal Optica, may help lead to improved atomizing sprays for more efficient, less polluting fuel combustion. It could also benefit numerous other industrial applications, such as the sprayed droplets that are typically used for making the powders in pharmaceutical pills.

Most broadly, the new technique could allow researchers to see which theoretical models best describe spray behavior. Current models are limited by the blurry views that scientists have of the interior of a droplet cloud. New imaging techniques that suppress this blur could allow scientists to design spray systems based on empirically validated predictive models, rather than relying on a mix of limited modeling and laborious trial-and-error design, as is often currently the case, says Berrocal.

Sprays are difficult to image partly because of their complexity; thousands of microscopic droplets are involved. The behavior of those drops then must be recorded in less than a millionth of a second to capture physical changes that might prove critical to understanding spray behavior, such as whether and how larger drops fragment into smaller ones. In the past, most attempts at imaging sprays illuminated them with visible light, but studies show that the droplets scatter anywhere from 86 percent to more than 99 percent of the light beam in all directions. Such optical strategies therefore often lead to blurry or completely obscured images of the interior of the spray.

One alternative imaging technique uses powerful x-rays, which droplets typically absorb, to create a silhouette of a spray. By analyzing the shadows the droplets make against a bright x-ray source, researchers can measure their density, which for instance can show how gasoline droplets are distributed within a spray, and in turn predict how the gasoline will burn. However, use of this strategy is limited because it usually requires large particle accelerators called synchrotrons to generate the intense x-rays.

Now Berrocal and his colleagues have developed a hybrid strategy that incorporates new versions of both optical and x-ray imaging methods to overcome some of those shortcomings.

The researchers’ technique first generates x-rays from a compact, tabletop laser-plasma accelerator developed by physicist Olle Lundh on the Lund team. Although this device is much smaller than a synchrotron, it can generate bright beams of x-rays with energies between 1 and 10 kiloelectronvolts, which is in the right range for 100-micron-wide droplets to absorb.

The device fires rapid, near-infrared laser pulses, each lasting just 38 femtoseconds (or 38 quadrillionths of a second), into a pocket of helium gas. The pulses generate a plasma, a cloud of electrically charged particles. This process, Lundh says, “can support electric fields 10,000 times stronger than in conventional techniques using synchrotrons, reducing the amount of distance we need to accelerate particles to the high energies needed to emit x-rays.” The resulting beam of x-rays is also relatively wide, large enough to image an area of spray that measures 20 by 20 millimeters. In comparison, synchrotron x-ray imaging of sprays covers areas measuring just 4 by 4 millimeters.

In parallel, the researchers use the same femtosecond laser pulses to perform an optical imaging technique called two-photon fluorescence imaging, which uses dye molecules that fluoresce only when they are illuminated by two photons at the same time. A camera is trained on the illuminated patch, tuned to the exact frequency of light that the dye molecules emit. The tightly focused, organized photons from the laser beam are likely to hit the dye in pairs, causing it to light up, if they hit it directly. Any photons that scatter, on the other hand, are unlikely to strike in synchronized pairs. As a result, scattered light doesn’t contribute to the fluorescent glow, making it possible to filter out much of the blurriness that scattering normally causes.

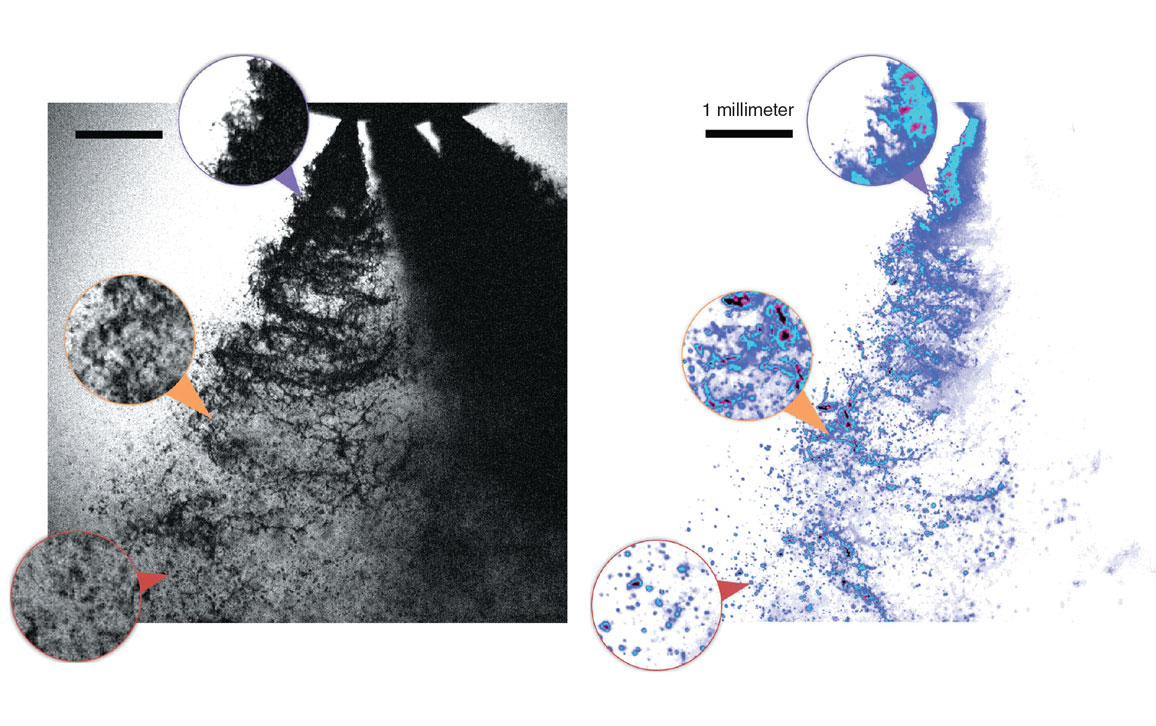

Berrocal and his colleagues have begun testing their imaging system using jets of water created by a commercially available automotive fuel injector. (They started with water because experimenting with fuels requires more safety precautions.) The optical portion of their system was able to measure droplet size, shape, and position in great detail, and the simultaneous x-ray imaging helped determine droplet masses. The ultrafast x-rays and laser pulses combined to create what was essentially a stop-motion effect, freezing the motion of the droplets for clearer imaging. The joint strategy was sensitive enough to measure water droplets roughly 5 micrometers wide, about one-fifth the size limit for synchrotron x-ray imaging, and produced a level of clarity beyond that which conventional optical imaging of droplets can achieve.

“There has been this competition with advanced optical techniques on one side and x-ray imaging on the other when it comes to sprays. It’s really nice to have a tool that can combine the two worlds into one,” Berrocal says. “By combining advanced techniques in the visible and x-ray regimes, highly complementary spray information can be obtained in a way that has never been achieved before.”

The researchers are currently expanding their technique to capture three-dimensional images of sprays. The next step would then be to boost the rate at which they can generate pulses. Right now they can produce one image every 10 seconds; their goal is one image per second, which would help scientists analyze how sprays evolve over time, Berrocal explains. He is also exploring the use of heat-sensitive dyes that would tell researchers the temperatures within the liquid droplets, another important factor in efficient combustion.

Taken together, these data could lead to cleaner-running cars and trucks, drugs that break down in the body at a more predictable rate, and improvements in many other industrial applications. The new imaging approach could also streamline testing. “The information we could provide modelers on how liquid is distributed everywhere in sprays could help provide evidence to validate which models of sprays work,” says physicist Diego Guénot, another member of the Lund research team, “so that moving forward, the models can become predictive.”

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.