This Article From Issue

March-April 2013

Volume 101, Number 2

Page 111

DOI: 10.1511/2013.101.111

A waterfall showcases the immense energy that can be found in all forms of water. But a damp piece of paper might not top the list of potential power sources. However, that’s all a new polymer composite needs in order to both roll about and generate a little electricity. As chemist Mingming Ma and his colleagues at the Massachusetts Institute of Technology explain in the January 11 issue of the journal Science, inspiration from tough-but-stretchy animal skin led them to the right combination of materials to make a film that is moved by water.

Dr. Ning Zhang

The composite is made from a relatively rigid polymer, called polypyrrole, combined with a flexible one, called polyol-borate. When the two long-chained chemicals are electrically deposited onto a surface simultaneously, they randomly intersperse and bond together to spontaneously form a film. The polypyrrole forms a stiff network to support the material. But in the presence of water, the interweaved polyol-borate breaks some bonds with the polypyrrole and joins up with water molecules instead. This reaction expands the polyol-borate, swelling the film overall. When the water evaporates, the reaction reverses, returning the film to its original shape.

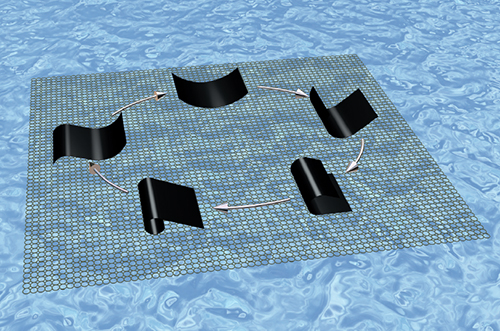

If the film is surrounded by a constant water level, Ma explains, it just rolls up into a tube and sits there. But if there’s a water gradient—more moisture, say, on one part of the film than another—that’s where it gets interesting. The team set up such a gradient by placing the film on damp paper, with the air humidity maintained at 20 to 30 percent.

“When the film absorbs water, the two sides curve up but the middle part still contacts the moisture,” Ma explains. “But with the two sides going up, the center of gravity goes up so the system gets unstable and falls in either direction. Now the side falls back to contact the moist surface, and still needs to curve more to get away, so it continues to roll and actually turns over.” The film takes about 5 seconds to complete a cycle, but Ma says the rate could be controlled by modifying the temperature and thus the speed of water evaporation. (Videos of the toppling films can be found at http://www.sciencemag.org/content/339/6116/186/suppl/DC1.)

During this process of toppling and flopping around, the film generates quite a lot of motion. The swelling and contracting is a bit like what happens in fast-twitch muscle fibers, so Ma and his group think that the films might be used as actuators—artificial muscles—for small robots. They have demonstrated that the films can lift a stack of glass slides 380 times their weight, and transport a cargo of silver wires 10 times heavier than themselves. The films can generate about 10 newtons of force—enough for a robot to do some useful work. Ma says that the size of the films could also be scaled up, because he and his colleagues found that a 9-centimeter-long film moved at the same rate as a 4-centimeter one. The films can be cut into any shape, but girth is a performance factor: Thicker films are slower but can lift more weight. Ma says the film’s movement can be guided: “If you stretch the film in one direction, it will curve in the other direction, so we can control the curvature by stretching.”

The mechanical energy from the film’s motion can also be captured as electricity. Ma and his colleagues coated one film with a piezoelectric material, which converts stress into electric power. The film was able to generate a micro-coulomb amount of charge within several minutes. This amount of charge was stored in a capacitor at a voltage of around 1 volt, which was enough to make a red LED flash. The films might be able to provide more electricity if several are wired to the same capacitor.

The group is exploring piezoelectric materials that are more efficient at converting mechanical energy into electric current, but Ma notes that even a low level of power may be useful. For instance, small environmental sensors that are distributed in remote regions, where it would be hard to change batteries, might benefit from being powered by just a little water. The films maintained their integrity in the lab after six months of open storage and hundreds of movement cycles, so Ma thinks they could survive an extended period of environmental exposure. “The film itself is very stable, chemically and mechanically,” Ma says. “For a sensor, it doesn’t need a very intense deformation or stretching. Although it moves, the mechanical stress generated is pretty small.”

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.