The Minneapolis Bridge

By Henry Petroski

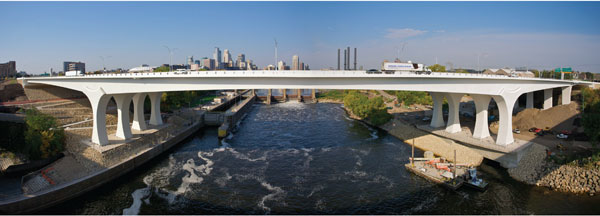

A replacement for a fallen structure rises to the occasion in less than a year

A replacement for a fallen structure rises to the occasion in less than a year

DOI: 10.1511/2009.81.444

Interstate Highway 35, which stretches from Laredo, Texas, to Duluth, Minnesota, is the main north-south artery running through the heartland of the country. Heading north, the road passes through San Antonio, Austin and Waco, before dividing into east and west branches that pass through Dallas and Fort Worth, respectively. After leaving that metropolitan area, the two routes rejoin to carry traffic on through Oklahoma City, Wichita, Kansas City, Des Moines and then once again dividing into an I-35E and I-35W pair that serves St. Paul and Minneapolis.

Until a couple of years ago, I-35 evoked Texas for me. When we lived in Austin, it was the road my family and I took south to Laredo for a day’s outing to the markets in Nuevo Laredo, Mexico. Known in the Austin area then as the Interregional Highway—or just the Interregional—I-35 was a wide man-made gash in the otherwise unremarkable network of roads through what was a slow and quiet town of modest proportions through which the lesser-known Colorado River flowed. Besides the river, the Balcones Escarpment, a visible manifestation of the Balcones Fault, is the principal natural gash in the local topography and signals that the Texas Hill Country lies to the west. Stretches of I-35 north of Austin more or less parallel the fault. Beyond that, I-35E and I-35W were the roads we took to the pair of big cities in North Texas after which the DFW airport is named. When we drove home for holidays, we left I-35 in Oklahoma for interstates that ran northeast. When we visited Austin a few years ago, after a hiatus of three decades, we found traffic on I-35 through Austin to be directed to the upper level of a double-decked highway. In all our travels on I-35 and other interstate highways, I seldom thought about the possibility of one of its bridges falling out from under us.

My primary point of reference for I-35 changed from Texas to Minnesota after August 1, 2007, when the bridge carrying I-35W over the Mississippi River at Minneapolis collapsed spontaneously during the evening rush hour. Thirteen people were killed and 145 more injured in the hundred or so vehicles that were on the bridge at the time of the structural failure that shocked the country and the world. Bridges carrying major highways are not supposed to fall apart so suddenly, though they occasionally do. It happened in 1983 to the I-95 bridge over the Mianus River in Connecticut and in 1987 to the New York State Thruway (I-90) bridge over Schoharie Creek. When it happened in Minneapolis in 2007, drivers already on the bridge, not to mention their passengers, not only had no warning, they had no chance to do anything about it. It was remarkable that the death toll was not greater than it was.

This can be attributed to how the bridge was constructed, and how it fell. The triangular arrangements of steel members comprising the trusswork designed to support the roadway from below acted like crumple zones in an automobile, absorbing energy as they were being bent, crushed and otherwise deformed as they impacted the ground and the riverbed. This inadvertent design feature slowed the descent of the roadway to a survivable rate, reducing a hard, life-threatening landing into a relatively soft one for many of those in vehicles traveling over the bridge that day, including a school bus full of youngsters. But the design of the steel truss was also to be the focus of forensic engineers and other accident investigators looking for an explanation of why the bridge failed after standing for so long.

My wife and I were driving north on other interstate highways at the time the accident happened. For most of our route from our home in Durham, North Carolina, to our summer retreat in Arrowsic, Maine, we followed I-95. Since we tend to talk rather than listen to the radio when we are driving long distances, I did not learn about the bridge collapse until the next day. When we reached Maine, the news came in the form of telephone and e-mail messages from newspaper reporters and producers of radio and television shows requesting interviews. A call from the op-ed page editor of the Los Angeles Times prompted me to write that evening about bridge failures in general terms, including some historical examples, something I felt able to do even without knowing much about the Minneapolis bridge that was in the news.

As with airplane crashes and other transportation-related incidents, the accident scene was soon under the control of the National Transportation Safety Board, which is responsible for carrying out investigations into causes. Normally, the NTSB studies and deliberates for many months, if not a year or more, before issuing what it will declare only to be a “most likely” or “most probable” cause of a failure. On occasion, however, when advance information might prevent similar accidents from occurring while it painstakingly carries out its investigatory business, the NTSB will hold news conferences to announce significant findings or potential theories.

The NTSB was not the only organization interested in investigating the Minneapolis accident. The State of Minnesota, and its Department of Transportation, certainly wanted to know what had happened. Minnesota and other states also wanted to know if there were any similar bridges that might warrant immediate concern and inspection. The I-35W bridge was designed and constructed in the 1960s, and there were probably scores, if not hundreds of other bridges of a similar design and age. Was there something about the design itself that caused the bridge to fail? Was there something about its being 40 years old? Were there historical precedents?

The same year that the Minneapolis interstate bridge opened to traffic—1967—there was another historically significant bridge collapse with some striking similarities. Silver Bridge, a chain suspension structure, had spanned the Ohio River at Point Pleasant, West Virginia, for four decades, but during the evening rush hour on December 15 the suspended roadway suddenly collapsed, sending dozens of vehicles into the river and claiming the lives of 46 people. The National Transportation Safety Board, which had been established only earlier that year, was charged by President Lyndon Johnson with determining the cause of the failure. Johnson also appointed a task force to study the effectiveness of bridge-inspection practices.

Even before there was a determination of the cause of the Silver Bridge collapse, a twin structure at St. Marys, West Virginia, was closed down because the nature of its construction made it impossible to inspect. That feature proved to be a key factor in the collapse of Silver Bridge: The method of connecting its steel eye bars to form the suspension chains made it virtually impossible to see if cracks were developing at the holes in the links. After three years of study, the NTSB issued a final report that indeed identified a critical crack in one of the eye bars as most likely initiating the separation of one of the bridge’s two suspension chains and the subsequent total collapse of the structure. The brittle nature of the steel, combined with the corrosive and vibratory environment, had allowed small cracks to grow unseen until they threatened the integrity of the structure. Such designs are, for obvious reasons, no longer used.

It was the West Virginia accident that had led to more stringent safety inspections, including the practice of inspecting major highway bridges like the I-35W span in Minneapolis at least once every two years. The Minneapolis bridge, which had been inspected annually for the 17 years prior to its collapse, had thus passed many inspections during its lifetime, but none had evidently uncovered an alarming flaw or fault in the structure. It was only after the collapse revealed incontrovertibly that the span had had a problem that post-mortem inspections commenced on the debris sitting in, above and next to the Mississippi River. After a while, the wreckage was moved to an NTSB-controlled site, protected for whatever inspectors might wish to examine it.

But even before the wreckage was moved, steel bridges around the country were inspected more closely than they normally might have been, with some being closed in the interest of prudence. And within a week of the accident, a consultant to the State of Minnesota who had been poring over engineering documents discovered a potential flaw in the bridge’s design. Its gusset plates, the flat steel sheets to which beam- and column-like components were riveted to form the joints of the truss, were suspected of being overloaded. The overloading may have been caused by the weight of almost one hundred tons of gravel, along with heavy construction equipment staged in one of the closed lanes, awaiting use in a resurfacing operation, that was sitting on the bridge at the time of its collapse. This asymmetrical loading beyond what the bridge had been designed to support could have caused the underdesigned gusset plates to reach their limit of resistance. The NTSB would, in fact, eventually come to a similar conclusion.

In the meantime, without its major Mississippi River crossing, Minneapolis traffic was disrupted, to say the least. There was an immediate need for a replacement bridge, but bridges are not built overnight. Neither engineers nor citizens wished to see the same (or any) flawed design used for a new bridge, so time had to be spent in design as well as in construction itself. By having the designing and building done by the same team, the process would be more efficient. The Minnesota Department of Transportation soon issued a request for bids, and within about 10 weeks of the collapse a design-build contract was awarded to a joint venture consisting of Flatiron Construction of Colorado, which describes itself as “one of the leading infrastructure contractors in North America,” and Manson Construction of Florida. The team promised to design and construct within less than 15 months a replacement bridge that would last for a hundred years. But construction companies do not as a rule design bridges, and so Flatiron had taken on Figg Bridge Engineers as a partner to do the actual structural design.

Photograph by Tim Davis, courtesy of Flatiron.

The bidding process was expedited, but the contract that appeared to have been awarded on the basis of sketches and artist’s renderings did not go unchallenged. Flatiron-Manson had not been the low bidder, and two competing bidders challenged the Department of Transportation’s decision, which a judge would later describe as being cloaked in secrecy. In fact, the bids were judged not solely on the basis of price; factors relating to aesthetics and contractor reputation and performance record had been taken into account. Flatiron’s design partner Figg was known for its striking, some would say artistic, designs. And Flatiron, which had worked with Figg on other similar bridge designs, had a well-established track record in building such structures. Furthermore, Manson specialized in marine construction and so had the expertise and equipment to work in the waters of the Mississippi River. Thus, there was a high probability that the team selected would deliver on its promises.

The bridge that had collapsed was a steel truss that was described as “fracture critical,” meaning that if one piece of steel in the assembly broke, the entire bridge would likely collapse. This kind of design would certainly not have been chosen for the new bridge—nor would any kind of steel bridge. The Flatiron-Figg design was of the concrete box-girder type, which would be erected by the balanced-cantilever method, a construction process with which Flatiron had extensive experience. Sections of the bridge would be cast on the idle lanes of the closed interstate, trucked down to the riverbank, loaded on barges there, and then returned to bridge level by means of cranes. Once hoisted into place, each new section would be attached to its mate with intersectional epoxy adhesives and then pulled tight with interior steel cables that would tie all the sections together. Unlike the supporting cables of a suspension or cable-stayed bridge, the post-tensioning cables would not be visible in the finished bridge, which was to take on the appearance of having slender and gently arcing girders supported by pillars sitting on the banks of the river. The replacement bridge was in fact to consist of twin parallel structures, one carrying northbound and the other southbound traffic. The main span of each was to be just over 500 feet, well within the envelope of experience.

Designing and building the new structure presented challenges beyond the technical. The Republican National Convention was scheduled to be held in Minneapolis in about a year, so Minnesota’s Republican governor wished to have a replacement bridge as close to completion as possible by that time. This helped drive the accelerated design and construction schedule, which the Democratic mayor of Minneapolis and his political allies cautioned against. Furthermore, there was an ongoing debate in the Twin Cities area and throughout the state between those who supported more road building and those who favored the development of mass-transit projects, such as light-rail lines. There was pressure to incorporate a light-rail system into the new bridge. The compromise was to produce a bridge design that would allow the addition of light-rail at some future time.

The basic design devised by Figg was presented to representatives of the affected community at a design charrette that was held just 16 days after the awarding of the contract. Laypersons were not expected to have input into the technical design of the structure, but they were called on to participate in the selection of some of its aesthetic features and embellishments. The new bridge was presented as a “functional sculpture,” incorporating conceptually the theme of “arches – water – reflection.” The arch theme tied the bridge into neighboring historic true arch structures; water acknowledged that the bridge did cross a river; reflection referred not only to the fact that the image of the bridge would be inverted in the water but also that the structure should evoke the historical significance of the bridge’s predecessor. Guided by the tripartite theme, the charrette engaged the participants in helping to choose the shape of the bridge’s piers, its color, and the nature of its lighting, railings and abutments—none of which affected the basic structural design.

Additional engineering considerations for the new bridge involved the use of “smart bridge” technology. All bridges move: They vibrate under the wheels of passing cars and trucks; their roadways expand as the temperature rises and contract as it falls; they strain under a heavy accumulation of snow; they bend to the wind; and they shake during an earthquake. The new bridge will do all these things, of course, but it will differ from a conventional one in having had more than 300 sensors embedded in its concrete parts to record and transmit via fiber optic cables data associated with expected motions and more. The data will be collected and analyzed at the nearby University of Minnesota to provide insight into the behavior of a real structure under real working conditions and to serve related research programs. Some of the sensors will also provide early warnings should anything on the bridge depart from expected behavior, thereby providing a supplement to traditional inspection procedures.

Photography courtesy of the Minnesota Department of Transportation.

In spite of the complications of politics, citizen involvement, winter construction and the incorporation of smart technology, the new bridge was completed in slightly more than 11 months. Indeed, the new bridge was opened to traffic on September 18, 2008—just after the political-party convention but more than three months ahead of schedule. It is officially named the St. Anthony Falls Bridge, after the natural falls that are situated just upriver of the structure. A 30-foot-tall abstract sculpture stands in the median at each end of the bridge to signal to drivers that they are entering onto a significant water crossing. These pylons consist of three closely spaced wavy columns that represent a “vertical interpretation of the universal symbol for water.” They were cast with a special mix of concrete that is capable of undergoing a chemical reaction with airborne pollutants to keep them from staining the structure. Thus, the pylons are expected to retain their gleaming white color without special maintenance.

All the while the new bridge was being designed and built, the design and remains of the old were being studied by forensic engineers. Early theories about the cause of the failure had included corrosion and metal fatigue, but the theory that the NTSB returned to repeatedly was the design of the gusset plates. Key plates were identified as being half as thick as they should have been, but this alone might not have caused the bridge to fail, since it had stood for four decades with the same thin plates. Just because something is underdesigned does not mean that it cannot do its job; it all depends on how large a factor of safety was employed. If, for example, a structure is designed with a factor of safety of 3 throughout, but for whatever reason it was built with a critical component only half as strong as it should have been, that part will still have a factor of safety of 1.5. In other words, the structure could hold 50 percent more than its design load.

Photograph by Tim Davis, courtesy of Flatiron.

The NTSB evidently realized this, for the board’s final report, which identified the underdesigned gusset plates as the most probable cause of the failure, also cited as a contributing factor the combined weight of the gravel and construction equipment that was parked on the bridge at the time of its collapse. This, in conjunction with weight that had already been incorporated into the bridge through earlier roadway upgrades, plus the rush-hour traffic at the time of the collapse, simply loaded the structure beyond what it could tolerate. The weak links were the gusset plates that were thinner than they should have been.

Such a scenario is not unprecedented in the history of bridges. In the 1840s, when iron bridges were being built at a frantic pace to keep up with the expansion of the railroads in Britain, a peculiar kind of structure became a standard design. This so-called trussed-girder bridge consisted of multiple cast-iron beams bolted together end-to-end and then tied together with wrought-iron rods. This hybrid structure had served the railroads well for shorter spans and so began to be used for spans of increasing length and decreasing factor of safety. One of the principal proponents of this bridge type was the engineer Robert Stephenson, who used it for a crossing of the River Dee. This bridge, which employed spans approaching one hundred feet, collapsed suddenly one day in 1847 under the weight of a passing train. The failure called into question the use of iron in railway bridges, but the immediate cause of the collapse appears to have been the addition of a layer of gravel to the roadbed just before the ill-fated train was scheduled to cross the bridge. The structure evidently could hold the additional gravel or the passing train, but not both simultaneously, so it failed.

As persuasive as the gravel-overload theory appeared to be in explaining the collapse of the Minneapolis bridge 160 years after that of the Dee, some engineers were not convinced. An investigation carried out independently of that done under the auspices of the NTSB focused not on the gusset plates and traffic and construction loads alone but on the corrosion factor. Since bridges do move as they heat up and cool down, it is necessary to incorporate into their design devices that are capable of allowing for such movement. These sometimes take the form of expansion joints, which carry traffic more or less smoothly over gaps that are wider in the winter than they are in summer. Another device is the roller bearing, which allows one end of the bridge deck to move a small amount but freely along the top of a pier, so that the structure neither pulls on the pier during periods of contraction nor pushes on it during periods of expansion. The roller bearing is designed to allow for this movement. If, however, the bearing becomes so corroded that it can no longer move freely, then the bridge can literally tear itself apart.

Photograph by Professor Robert Dextor, courtesy of the University of Minnesota.

August 1, 2007, was a very hot day in Minneapolis, so the thermal expansion of the truss structure supporting the I-35W bridge deck should have been close to if not at its greatest. Furthermore, if the roller bearings were so corroded that they were frozen up, then the truss would not have been allowed to expand freely. This could have added additional compressive stresses to key members of the truss. Since the bridge also contained thin gusset plates, some of these may have been bent by previous loading conditions and so represented doubly weak joints in the structure. The combination of corroded bearings, bent gusset plates, high temperatures and an overloaded roadway could have caused some truss members to fail and so have been the root cause of the collapse. This is what lawyers representing victims’ families were expected to argue in court as they maintained that the engineering company responsible for inspecting the bridge and the construction company responsible for parking its trucks and materials on the bridge were at fault for the tragedy.

In 2008, Minnesota established a fund to compensate victims of the bridge collapse if they agreed not to sue the state. In an attempt to recover money paid out of the compensation fund, Minnesota initiated lawsuits against the successor of the engineering firm that designed the bridge, claiming that the gusset plates were not designed properly, and against the contractor that placed the heavy materials and equipment on the bridge, claiming that the transportation department was not notified of the action. These firms were also being sued independently by survivors and families of the accident victims, but, as of the summer of 2009, the state had not initiated a suit against the firm that served as an engineering consultant on the bridge. This was confusing to observers, who noted that lawyers for the victims were accusing this firm of being negligent, in that over the course of three years prior to the collapse it had done “nothing to rectify the known problems with the bridge,” thereby playing a “substantial” role in the failure.

Regardless of what might transpire inside and outside the courtroom, the failure of the I-35W bridge in Minneapolis has become an inextricable part of the story of crossing the Mississippi River there. The rusted steel truss that collapsed may have been replaced with a clean white sculpted concrete span, but few people crossing over the new bridge—whether everyday commuters or vacationers passing through on their way from Dallas or Duluth—will do so without being reminded, by the wavy pylons if necessary, of the events of August 1, 2007. But those same drivers and passengers should also realize that what happened on a hot day one August is as rare as a March without snow in Minnesota. The fallen bridge had carried 140,000 vehicles a day—perhaps 200,000 people per day. In the 40 years that the old bridge stood, well over a billion people may have crossed it. Such large numbers do not diminish the tragedy that befell those who died or were injured in the accident, but it should reassure us that such incidents are indeed rare. And they can be expected to be even rarer in newer bridge designs.

©Henry Petroski

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.