This Article From Issue

July-August 2001

Volume 89, Number 4

DOI: 10.1511/2001.28.0

Enriching the Earth: Fritz Haber, Carl Bosch, and the Transformation of World Food Production. Vaclav Smil. xx + 338 pp. The MIT Press, 2001. $34.95.

The staple food of most people for a hundred centuries has been for the most part the seeds of certain grasses, our cereal crops. Early farmers soon recognized that fields never allowed to rest became impoverished and that planting legumes restored the land. Peas and lentils were sown along with cereals on the first farms of the Middle East; the New World grew beans and maize, soy and mung were planted alongside Asian rice, and peanuts aided sub-Saharan root crops. These legumes added nitrogen to the soil—and to the diner. Thus our agricultural dependence on nitrogen (supplied by the nitrogen-fixing bacteria that live in legume roots) predated the discovery of nitrogen by millennia.

The story of nitrogen in agriculture is told in fascinating detail in Enriching the Earth, which is really three books in one—an authoritative mix of ecology, biochemistry and chemical engineering. It presents the chief agricultural invention of the 20th century: the industrial synthesis of ammonia from nitrogen and hydrogen, which has been used to fertilize the crops that have fed our times and will nourish the billions to come. Broad and imaginative, meticulously argued and fully documented, yet lively and readable, this surprising book (one of more than a dozen fine books by geographer Vaclav Smil) opens a door wide to a dimly lit corner of high-tech, to offer us a new understanding of major change.

With industrialization, the burgeoning of human population and of its expectations demanded higher grain production. Wide new lands were brought into cultivation in Russia, the Americas and Australia. Well-off countries that had little new land sought new nitrogen sources to increase their own grain yields. One source of plant nitrogen was the main effluent of 19th-century urban transportation—horse manure. In Paris, a million metric tons were collected annually for the market gardens. In Manhattan, manure was shipped out to the garden plots of Brooklyn and Queens, and produce was ferried back. Night soil (human waste) was long a recognizable, if riskier, source of fixed nitrogen, and in China up to three-fourths of that supply was recycled to outlying fields.

Enriching the Earth.

About 1850, an ecological curiosity opened a frenzy of trade in usable nitrogen. Whole cliffs of guano, the soluble nitrogen-rich excreta of seabirds, had piled high on a few rainless islands off the shores of Peru. Soon there waited at sea a whole fleet of three-masters, enough to dispatch a shipload a day to distant ports. Some 20 million tons were moved until the guano piles were leveled by 1870. The urgent trade shifted surprisingly to Chilean deserts nearby, where deposits of caliche, a crude mineral conglomerate of salts, including nitrates, had been laid down during the late Tertiary and Quaternary eras. The grain harvest of the industrial world would be nourished well into the horseless years by vessels beating around the Horn. Export of this fossil nitrate peaked in the 1920s.

With the birth and development of chemistry in the late 18th and early 19th centuries, it became plain that every plant and animal substance holds combined nitrogen. By the 1830s the nitrogen in many complex organic compounds could be released in a soluble form. In 1840, the great Justus von Liebig, agronomist and chemist, noted atmospheric nitrogen’s "indifference to all other substances"; in air, the two N atoms are bound by a triple bond so strong that few biochemical reactions can break it. The vast ocean of air holds a million tons of N2 for every single human (a lifetime supply for one person is about two tons, most of it soon recycled); yet this nitrogen is mainly inaccessible. (Natural lightning does crack dinitrogen bonds, however, making an uncertain contribution through rainfall to the biological cycle.)

By 1888 Hermann Hellriegel and Hermann Wilfarth had shown definitively that nonleguminous plants grew better with the addition of calcium nitrate but did not thrive when given a suspension of raw (unsterilized) soil mixed with water. Legumes responded erratically to added nitrate but strongly to soil suspensions. The nodules on legume roots proved to be not mere storage organs, but rather the site of active enzymatic nitrogen fixation with the aid of symbiotic microorganisms in the soil.

By now we have identified those microorganisms and many other prokaryotes that also fix nitrogen, largely in humus-rich soils. Yet decades of efforts at bioengineering to extend the legume symbiosis to the roots of other crops have not yet shown promise. It is certainly no single-gene affair.

Regarding the need for more fixed nitrogen, Sir William Crookes declared famously in 1898, "It is the chemist who must come to rescue." Today at least two-fifths of the population owe the food that provides their daily nitrogen intake to fertilizers produced through an unprecedented synthesis of ammonia from its elements.

As Smil aptly describes in his fourth chapter ("A Brilliant Discovery"), the famous names of physical chemistry all tried their hand at ammonia synthesis. Fritz Haber, a clever professor at Karlsruhe, with broad experience and a taste for systems, was first set to the task by an inquiring firm in Vienna. Soon the great German dye and drug firm BASF (Badische Anilin- & Soda-Fabrik) put Haber under contract for research on nitrogen fixation. On July 2, 1909, Haber and a colleague in the laboratory at Karlsruhe produced a continuous flow of liquid ammonia, about a pint in five hours, from hydrogen and nitrogen fed into a hot five-inch iron tube a couple of feet tall, the gases at 200 atmospheres pressure over an osmium metal catalyst. BASF experts were present—although BASF metallurgist and creative engineer Carl Bosch had had to leave early—and they were joyous.

It was Bosch who led the march to synthesis on a world scale. He had free rein to arrange the gas supply and the high-pressure converters and to select new catalysts. His pressure tests burst the steel pipes in a week, revealing that the dense hydrogen had decarburized inner layers to a hard and brittle stuff. Bosch designed a thin inner liner of soft steel that sealed the gases in, its pressure load supported by a stout perforated steel jacket. Hydrogen diffusing slowly through the liner was flushed away by flowing nitrogen. Soon enough the heat of the main exothermic reaction was used to offset most heat losses. Trial and error produced within a year a cheap iron-based catalyst.

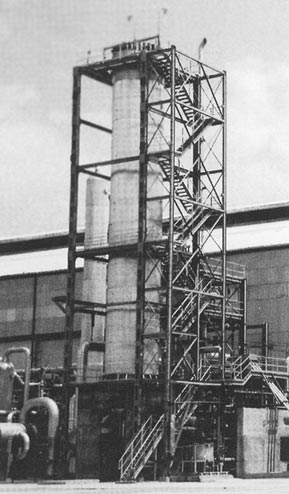

Construction of a plant with commercial capacity at Oppau began in 1912. Its big converters were 10 times the height of the first iron lab tube; they turned out not a pint, but a ton of liquid ammonia in five hours. More than a hundred acres of novel overhead high-pressure piping linked many process sites; by 1914 daily production of usable nitrogen had reached 20 tons.

Once the guns of August opened fire in 1914, the plant switched from producing the fertilizer needed to replace Chilean nitrate (which was being blockaded by the Royal Navy) to producing artillery explosives (from ammonia oxidized to nitric acid) for use in trench warfare. Fixed nitrogen is as indispensable for military explosives as it is for grain.

Fearful of bombers after one French air raid, Bosch proposed a new plant in Saxony, the heart of the brown coal region, with a sixfold capacity increase. That plant burned lignite to raise steam for the compressors. By spring 1917 both giant plants (which are pictured in the book) turned out bulk sodium nitrate out of air, coal and by-product soda, making it possible for Germany to continue fighting despite the tight naval blockade.

Enriching the Earth.

In the year 2000, Haber–Bosch synthesis worldwide produced about 2 million tons of ammonia a week. For the 6 billion of us to be fed now, Haber– Bosch synthesis provides more than 99 percent of all inorganic nitrogen inputs to farms. Synthetic ammonia supplies about the same nitrogen tonnage in fertilizer for our crops as all green nature gains both from its microorganisms and from lightning. The raw materials for Haber–Bosch synthesis are atmospheric N2 and the natural gas that supplies both hydrogen and most of the energy. Haber–Bosch today uses energy quite frugally; only one-sixtieth of commercial fuel worldwide is now used to make ammonia.

The country that now synthesizes most ammonia is neither Germany nor Japan nor the United States, but the land where the most people sit daily to table—China. About one-third of its limited natural gas is used to make fertilizer, and in many older, smaller plants much coal is used as well. Children in the developing world feed on crops grown with fertilizer made from synthetic ammonia, and the 2 or 3 billion more of us who will arrive by mid-century will do the same.

The biggest single Haber–Bosch converters today produce 30 times as much useful nitrogen as did those of World War I. The half-dozen competing design and construction firms behind such modern plants include the chemical giants, but Haldor Topsøe, an ingenious Danish firm, built the two biggest units. The locomotive-like compressors of early days have become elegant rotary centrifugal pumps. The big converters are now paragons of energy efficiency, using only 20 percent more energy than is necessary in principle for the industrial process. Scrupulous purity of every gas stream preserves the catalysts. The reforming of the natural gas feed to provide both hydrogen and gas for fuel in the typical modern plant is a clever integration introduced in 1963 by the Houston firm M. W. Kellogg.

Smil reckons that production of ammonia through Haber–Bosch synthesis will plateau in the future. The side effects of nitrogen waste are a genuine health problem, but one that is coming under control; for instance, the river Rhine is overly rich in nitrogen, but its waters are improving and will soon become safe. New fertilizer application procedures should result in less waste, even from the paddies of Asia. Perhaps molecular biologists can one day match the success of the physical chemists of 1909 with transgenic cereals able to fix nitrogen from air, although at some cost in caloric yield.

In a nine-page postscript, the personal lives of Haber and Bosch are sketched. The "fulfilled and tragic life" of Fritz Haber is moving; he was exiled in 1933 by the Germany he had served all his life, perhaps too well, both for war and for peace.

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.