Copper, Heal Thyself

By Fenella Saunders

Nanocrystalline structures help materials self-repair radiation damage

Nanocrystalline structures help materials self-repair radiation damage

DOI: 10.1511/2010.85.290

A single particle, such as an atom or a neutron, when fired into a piece of copper, causes a fountainlike cascade of disturbance, knocking countless copper atoms out of their positions in the metal’s crystalline structure. A few trillionths of a second later, most of the atoms settle back into the crystal’s lineup, but a handful are permanently displaced, misaligned and unable to fit back in anywhere. If that material is in an environment with radiation, such as part of a nuclear reactor, over time those wayward atoms migrate and build up on the part’s surface, leaving behind voids that can make the material brittle. “After irradiation the size can increase up to 10 percent because of the atoms moving to the surface,” says Blas Uberuaga, a materials scientist at Los Alamos National Laboratory. “And that’s bad because if you make parts that all fit together, and then they swell, nothing fits together like it’s designed to.”

With the development of new fusion and fission reactors, researchers are looking for more radiation- resistant construction materials. It’s known that materials with a nanocrystalline structure often resist radiation damage better than regular, “bulk” versions of the same compounds. In the former, the material is made up of tiny grains, each one of which is a single crystal. When the grains are agglomerated, their crystal lattices don’t line up, so there are boundaries between the grains. Such grain boundaries are undesirable in some applications, such as in electronics, where they impede electron flow, but they are known to make substances stronger as well as more resistant to radiation damage. However, until recently the complete mechanism behind this radiation resiliency was not well understood on the atomic scale.

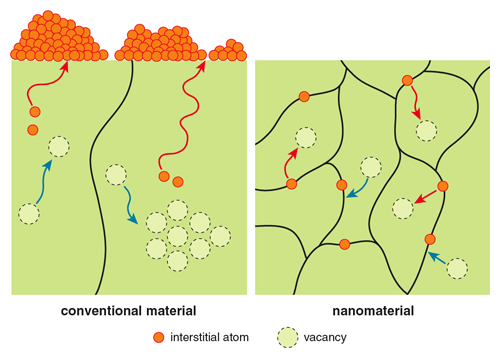

As Uberuaga, Xian-Ming Bai and their colleagues report in the March 26 issue of the journal Science, the group performed computer simulations of nanocrystalline copper undergoing radiation damage to figure out what happens inside the metal. The loose atoms, a type of defect known as interstitials, are attracted to the grain boundaries because there’s a little more room there than in the rest of the crystal. “Conventionally it has been assumed that once a defect gets to a boundary it just disappears, it gets very quickly to the surface or something like that,” says Uberuaga. However, their simulations found something new, as Bai explains: “We found that some of the absorbed interstitials at the grain boundary can come out to annihilate vacancies. So this is a new mechanism behind the self-healing phenomenon.”

Rather than just acting as a transport route to the surface, the grain boundaries seem to be a temporary sink for the loose atoms. The vacancies diffuse through the material much more slowly than the interstitials. But in a nanocrystal material, the chances are good that a grain boundary is relatively nearby, which can hold the atom until it finds a vacancy. “If the interstitials just got swept away somewhere else, that healing would not be able to occur. So that local trapping is crucial,” says Uberuaga.

In addition, the large number of grain boundaries in nanocrystalline materials gives the vacancies a shorter finish line for their catch-up race. “The vacancies don’t have to diffuse all the way to the boundary. There’s this extra zone in our simulation of about a nanometer or so where the interstitials can come out and directly zap the vacancies,” says Uberuaga.

Bai and Uberuaga suspect that the self-healing mechanism they’ve found will work with certain other metals and ceramics, and could reopen the consideration of whole classes of structural materials thought not to be sufficiently radiation resistant for use in reactors. Radiation does tend to make the crystal grain size grow over time in some metals such as copper, but using an alloy of two materials that don’t mix, and therefore can’t create larger crystals, could solve that problem. A bigger roadblock may be that nanocrystalline materials are not yet mass-produced. “There are a number of challenges like that before any kind of reactor material is really designed from the nanoscale,” says Uberuaga. “But these results give some insight into what kind of interfaces you might need to get some benefit in nuclear environments, both for fission and fusion reactors.”

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.