A Chemist's Guide to 3D-Printed Cuisine

By Matthew Hartings

Amateurs and entrepreneurs are producing uniquely shaped foods, from confections to meat alternatives to astronaut meals.

Amateurs and entrepreneurs are producing uniquely shaped foods, from confections to meat alternatives to astronaut meals.

In 2011, graduate students Kyle and Liz von Hasseln were using an old Z310 gypsum 3D printer to create architectural models in their home in Los Angeles. Then inspiration struck: They realized the same 3D-printing technology could be applied to food, and could be used to build confections with structures that had never been possible before.

The von Hasselns eventually developed and patented a method for printing complex edible objects. In 2012, they founded the Sugar Lab and began to partner with prominent chefs all over the world. Sugar Lab is a boutique startup that is just beginning to investigate the vast and wild possibilities of 3D-printed foods. Many others are exploring this area as well: high-end chefs, companies trying to replace meat and fish with printed alternatives, and—perhaps most excitingly—a vast community of home DIY types who are taking food where it has never gone before.

Access to printers (through public libraries, makerspaces, or purchase for as low as $100) has substantially lowered the barrier to entry into this world. Additionally, online communities such as Thingiverse, Cults, MyMiniFactory, and many more provide open-access resources for printable files and printing best practices that give valuable guidance for novices. Thingiverse alone now hosts more than two million files.

I am a chemist who designs new materials for 3D printing. In my research, I have printed objects that can remove environmental pollutants or that can store hydrogen gas for fuel cells, among other applications. I am also a food chemist. Although I have never developed my own processes for printing food, I have printed foodstuffs, such as peanut butter and Nutella, as part of my research. For me, Nutella is a benchmark, of sorts. It has just the right consistency (thickness and squeezability) to match some of the specialty materials I am developing. As a parent who needs to feed Nutella-hungry teenagers, I am partial to the argument that this hazelnut treat is not cheap. But in my lab, where research and development are time-consuming, the ingredients I use bust the budget in comparison. Printing Nutella is a way to make sure that when I print for my experiments, everything will come out just right. My goals are practical, but I have to admit that printing food is also simply fun.

Sugar Lab / Currant 3D

There is something quintessentially sci-fi and futuristic about a machine that can prepare any number of dishes with the push of a button. For home amateurs, 3D-printed foods offer a creative outlet and an opportunity for play. For chefs, 3D printers are a tool for crafting food in totally new ways. In the long run, 3D printing has the potential to create foods that are more sustainable, less cruel, and more creative for all of us.

For any type of 3D printing, edible or otherwise, the style of printing dictates the kinds of materials that can be used, and what can be made from them. The most recognizable style of 3D printing is based on extrusion. People who played with Play-Doh as children will remember the press that would squish out different shapes of Play-Doh pasta. That’s what 3D printers do, too.

The pasta company Barilla has taken that childhood joy and used it as the inspiration for a 3D printer that can make all sorts of new pasta shapes. Their printing venture, BluRhapsody, has a number of inventive pastas in different sizes and shapes that are available for purchase. What intrigues me most about these pastas, along with how they look on a plate, is their ability to hold and conceal sauces until the diner cuts them open. In the culinary world, individual styles of pasta are known to be compatible with specific kinds of sauces. For example, heavy cream-based sauces and meat ragus pair better with thicker noodles such as tagliatelle, while thinner sauces with even consistency pair better with spaghetti or angel hair. With their new 3D-printed pasta shapes, Barilla can help chefs innovate in their pasta and sauce combinations.

BluRhapsody

What 3D printing can accomplish that regular pasta making can’t is performing complicated patterns of extrusion. During extrusion, some material is pushed through a small nozzle and deposited on a platform. The nozzle moves horizontally around the platform, depositing material as instructed by a computer program until the object fully takes shape.

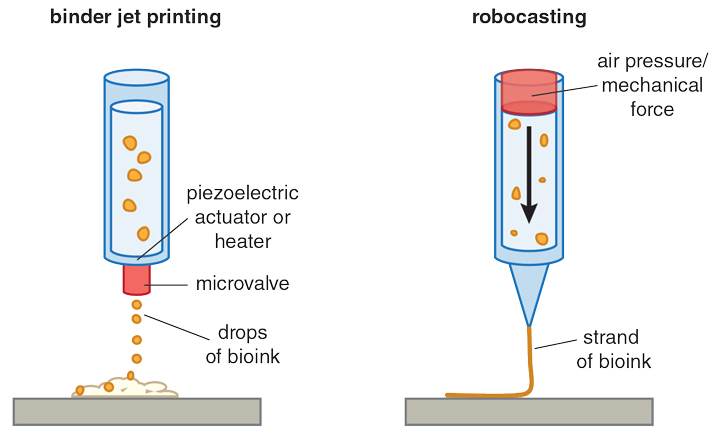

The prototypical extrusion printer uses a spool of plastic that is passed through a heated nozzle during a print. These are fused deposition modeling (FDM) printers. Needless to say, typical 3D-printing plastics—such as acrylonitrile butadiene styrene and polylactic acid—are not very tasty or healthy. The extrusion-based printers used in 3D food production are similar to FDM printers; however, instead of using a spool of plastic, they typically print using liquid that is held in a syringe. Printers that work in this way are termed direct ink writing, bioprinting, or robocasting.

The most important material property for robocasting is that the extruded material, or ink, needs to hold its shape after it is placed on the platform where the structure is being printed. In my lab, for example, Nutella is one of the inks that I print. There are a number of ways to design a printable ink. One system involves keeping the liquid in a heated syringe and printing onto a cooled or room-temperature platform where it will solidify rapidly. Printing chocolate or liquids that contain gelatin or agar is done this way; they are liquid while in the warmed syringe and immediately set when extruded onto the cooler platform.

Adapted by Barbara Aulicino; CC BY-NC-ND 4.0

A second way to achieve a 3D shape is to use a chemical fixing agent to set the printed liquid into a solid. An example of this method involves printing a viscous, water-based ink of sodium alginate into a container of water with calcium ions. The calcium ions are able to set the alginate into a solid. People who have played around with techniques from molecular gastronomy at home will immediately recognize these as the same ingredients used to make fruit caviar. The groundbreaking chef Ferran Adrià developed the technique for making fruit caviar (colorful spheres of fruit juice encased in a Jell-O-like shell) using the same ingredients, and intrepid 3D printing enthusiasts have co-opted Adrià’s innovation for their own uses.

Another common approach to designing a printable ink involves a thixotrophic liquid, which eliminates the need both for cooling and for chemical fixing agents. Thixotrophic is just a fancy word for a material that flows like a liquid when pressure is applied but doesn’t flow when there is an absence of pressure. This property may seem strange, but it is one we rely on almost daily. Ketchup and toothpaste (and Nutella and peanut butter, too) are all examples of thixotrophic materials. To get a good feel for this method of 3D printing, imagine a tube of toothpaste. If you remove the cap and turn the tube so that the open end is facing the floor, nothing happens. It is only when you squeeze the tube that any toothpaste comes out. Additionally, when you put toothpaste on your toothbrush, it holds its shape indefinitely. This is precisely the type of property that is targeted for robocasting thixotrophic inks.

Robocasting is a wonderful technique for exploring and experimenting with different 3D-printing materials. The only requirement is that the user must select appropriate flow properties for their ink. There are a number of commercial food-safe hydrocolloids available to help optimize these inks. Martin Lersch, a professional chemist and expert in modernist cuisine, has organized a recipe collection called Texture on his blog, Khymos, that highlights a number of hydrocolloid-thickened liquids. Texture is a great place to start for those who want to make their own robocasting inks. Although Lersch doesn’t refer to them as inks, he lists several recipes that will produce printable inks. If you’re curious, give the olive oil soba noodles a try! The methyl cellulose used in this recipe is a material I use in my research lab in designing printable inks, to give them just the right consistency for printing.

Natural Machines

Perhaps the biggest impediment to robocasting printing for culinary purposes is the availability of suitable printers. You can purchase food- or chocolate-specific printers, but they are costly, typically more than $1,000. I would suggest one of two options here. First, there are several cheaper, commercially available ceramic/clay printers that can also print food-based inks. Second, one could convert a FDM printer into a direct-ink-writing printer through some fairly straightforward modifications. I have recently made these modifications to one of the printers in my own lab following directions put together by materials scientist Adam Feinberg and his coworkers at Carnegie Mellon University. One of the great things about 3D printing is the availability of open-source hardware and software, which enables people to get exactly what they want out of their experience.

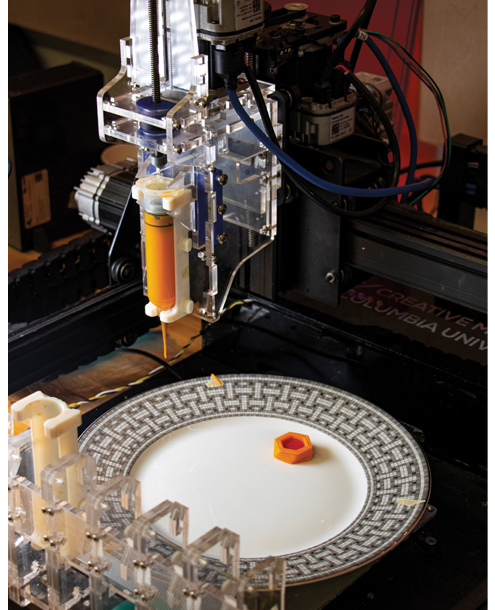

© Jonathan Blutinger / Columbia Engineering

In addition to robocasting, there is a whole other technique for printing edible objects, called binder jet printing. Binder jet printing (also known as powder bed and inkjet printing) is based on a process in which particles of a powder (such as cornstarch or sugar) are glued together. Sugar Lab, for example, uses binder jet printing to make candies and other decorative, edible pieces. In these printers, there is a reservoir for the powder and a build container where the powder comes together with the binding agent. Finally, there is a printhead (like in an office inkjet printer) that contains the binding agent to hold the powder together. At the beginning of the print, the reservoir is full and the build container is empty. The print starts when the bottom of the reservoir is raised and some of the powder is pushed into the build container. The inkjet printhead deposits “glue,” such as food-grade wax or sugar syrup, at precise locations on the surface of the build container to selectively cohere some particles. At this point, the build surface is lowered, the reservoir surface is raised, the process starts over, and these steps repeat until a full object has been glued together.

The user has several options for tailoring materials with binder jet printing. The first step is deciding which powder to use. For food printing, fabricators most commonly use sugar-based powders. Many other pantry ingredients are already available in powdered form as well, although most of these are not pleasant to eat on their own. An adventurous user could make their own, ready-to-eat powder blends with combinations of sugar, cornstarch, chocolate, and other flavorings. Another option is to use cyclodextrin, a specialty chemical derived from corn (N-Zorbit is a commercially available cyclodextrin) that can be mixed with an oily ingredient to make it the right consistency, resulting in ingredients such as powdered butter or powdered Nutella.

The other important decision in binder jet printing is which type of glue to use. In practice, most of the interesting creative choices come up at this juncture. The process here is analogous to the way an office color-jet printer uses a set of ink cartridges to produce color images on printed paper. A binder jet food printer can use multiple color cartridges as well, each containing food-grade dye, to create an elaborately artistic food print. A major difference between the office printer and the binder jet printer is that the binder jet cartridges also need to contain a glue to hold the particles together. That glue can come in several forms, depending on the powder used.

Although 3D printing enables the creation of a wide variety of elaborate forms, one of the most popular applications of 3D food printing is mimicry of familiar foods. Often, business ventures that 3D print foods have focused on making vegan or lab-grown mimics of animal-based foods. Investors have put billions of dollars into start-ups in this space, and the price of producing cell-cultured meat has dropped from a burger costing $330,000 in 2013 to about $9.80 in 2022.

Reuters / Amir Cohen / Alamy Stock Photo

Plant-based foods have the potential to remove many of the negative aspects of animal-based diets. Reduced land, water, and energy use, reduced greenhouse gas emissions, and increased nutritional value are commonly cited justifications, although none of these goals can be met with current efforts in plant-based meat alternatives. There are two main ways to produce animal-free meats. The first is to use all vegan ingredients, which is how the Impossible Burger is produced. The second is to use lab-grown meat products. These cultured meats are nearly identical to the muscles that develop in animals, with the crucial difference that they are grown from cells in a laboratory. In late 2022, the U.S. Food and Drug Administration approved the first lab-grown meat for human consumption: chicken meat produced by Upside Foods. Although both of these manufacturing methods can generate foods with meatlike flavor, matching the texture of a chicken breast, steak, or roast is a challenge that only 3D printing can meet.

The value of the 3D printer is that it can assemble ingredients in a form that resembles the structure of real meat—which veggie burgers and even Impossible Burgers do not do. Whether using plant-based meat substitutes or lab-grown meats, the race is on to bring 3D-printed steaks to market. Two companies, Redefine Meat (plant-based) and Steakholder Foods (lab-grown) are aiming to hit the market first. The problem is that replicating a steak poses a number of specific difficulties that must be overcome.

In late 2022, the U.S. Food and Drug Administration approved the first lab-grown meat for human consumption.

There are many different properties that make a steak a steak. First and foremost is composition. A steak isn’t a homogeneous material. It is primarily muscle interspersed with a marbling of fat. Both the fat and the muscle have different culinary properties, and 3D printing can facilitate a realistic arrangement of “muscle” and “fat.” The cooked texture is important here, too. Looking specifically at the muscle portions highlights these challenges. We have a number of different expectations for our cooked steaks: Rare, medium, and well-done are all points along gradients of steak “doneness” that are dictated by structural changes of the proteins actin and myosin.

Steaks can also be characterized as having distinct fibers. These are most recognizable when eating roast beef, but steaks display a fibrous nature, too. Additionally, a steak must be able to undergo the Maillard reaction—the chemical changes that occur during searing that bring a crispiness to the exterior of the steak along with the darkened color and enhanced flavor. A 3D-printed steak must also have the right color, taste, and aroma to be appealing.

So far, Steakholder’s beef morsels are a 3D-printed meat that is getting close to reaching the commercial market. Redefine Meat’s products are available only in select restaurants for the time being; it will take time to scale up production to the point where these products will be available in supermarkets.

So how have Redefine and Steakholder done so far? Tim Anderson, a London-based chef, recently wrote for 3Dprint.com that the texture of the newest iteration of 3D-printed steaks is a “triumph,” but that the appearance, juiciness, and flavor leave much to be desired.

Aleph Farms / Technion–Israel Institute of Technology

Other pushes for the 3D printing of realistic food mimics have come from the military and from the field of space exploration. In both these arenas, long deployments go hand in hand with a lack of fresh food because of spoilage and storage issues. If nutritious and appetizing food mimics could be produced from shelf-stable packets of 3D-printing inks, the quality of life for soldiers and astronauts would be increased. One NASA-supported project developed a 3D printer that can make a pizza, even spawning a company, BeeHex, to commercialize the technology. More recently, NASA started a Deep Space Food Challenge that is funding research into devices that can fabricate familiar foods (including a proposed food replicator from BeeHex) for long-duration space missions. This example is another product in development that is not quite ready for prime time. As with 3D-printed steaks, these companies seem to be slowly working their way toward the commercial market.

For everyone from home foodies to experimental chefs to commercial start-ups, the primary appeal of 3D printing foods is that it allows culinary creations that are unlike anything that has existed before. For now, most of the action is taking place at the makerspace or boutique level, because the tech is still so new and unexplored.

© 2016 Modernist Pantry, LLC. All Rights Reserved.

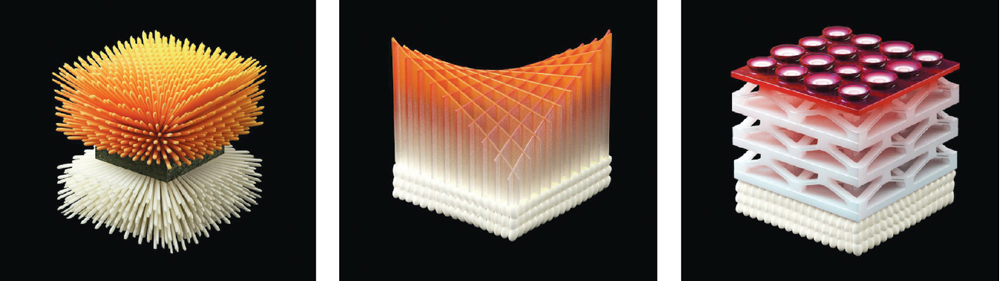

Sushi Singularity is a high-end Japanese restaurant planned in Tokyo that has embraced the flavors and textures of sushi while also exploring novel structures. Their 3D-printed food experiments include cell-cultured tuna in a filigreed cube, and octopus sculpted in a honeycomb lattice with negative stiffness (see figure below). Most of their printing appears to be extrusion-based, using components that undergo computer-controlled mixing to generate the right flavors and textures. They also use a powder-based printing technique that incorporates high-powered lasers to fuse powders together.

© Team Open Meals/Sushi Singularity

At Sugar Lab, the von Hasselns and their team keep tinkering with powder and glue recipes to explore new food geometries. They have 3D printed cocktail garnishes in the shape of cut diamonds that add bitters and sweetness to a drink. They are also exploring complex geometries, from icosahedron truffles to bouillon “cubes” in the shape of emblems for the members of the K-pop band BTS.

The great thing about 3D printing foods is that most possible foods in this space haven’t been made yet.

The first commercial experiments in 3D-printed food products are necessarily exotic and expensive, because they are early forays into the huge potential for printing foodstuffs; 3D printing is an enabling technology through which people can turn their imaginations into reality. As a scientist and food lover, I am intrigued by what people have accomplished so far. I really want to try a 3D-printed steak! Even though they don’t yet live up to their standard-bearers, it’s only a matter of time before the flavor and appearance come around. I am also excited to see what completely new types of foods (that aren’t trying to be something else) will emerge from this market. In either case, I hope that people recognize that change typically happens more slowly than we anticipate. It will take a while to print the perfect steak or pizza. It will take a while to experiment with formulations to get flavor and appearance just so. And it will take a while for regulatory agencies to grant approval, and for us to then see adoption on the market.

NASA

However, I think the results will be worth the wait as we see where boundaries are pushed. I am expecting to do my own experimentation in pushing those boundaries. Maybe that means printing a version of Willy Wonka’s Three-Course Dinner Gum using controlled-release polymers. Or it could mean figuring out how to replicate the properties of complex pastries. The great thing about 3D printing foods is that most possible foods in this space haven’t been made yet. There’s lots of room to play. I hope to see many of you on this journey.

Click "American Scientist" to access home page

American Scientist Comments and Discussion

To discuss our articles or comment on them, please share them and tag American Scientist on social media platforms. Here are links to our profiles on Twitter, Facebook, and LinkedIn.

If we re-share your post, we will moderate comments/discussion following our comments policy.